This comes as nearly all of the respondents (99%) surveyed in HP’s latest Digital Manufacturing Trend Report believe that digital manufacturing technologies can lead to economic growth. As a result, decision makers are looking to transform their business models, with 77% of those surveyed indicating that they will invest in digital manufacturing technologies such as industrial 3D printing, within the next 12 months.

HP and members of its customer community, along with industry thought leaders, showcased the power of digital manufacturing at its annual global HP Innovation Summit. HP’s Digital Manufacturing Trend Report underpinned the Summit’s panel discussions, examining the current state and future outlook for digital manufacturing technologies.

The benefits of 3D printing in particular are being recognised in the UK, a process increasingly being seen as a more viable alternative to traditional manufacturing. The most cited benefit of this technology by respondents is increased speed to market, with 79% of those surveyed agreeing that additive manufacturing/3D printing is helping their businesses become more agile, whilst four-in-five (86%) are expecting to benefit from economic growth after adopting this technology.

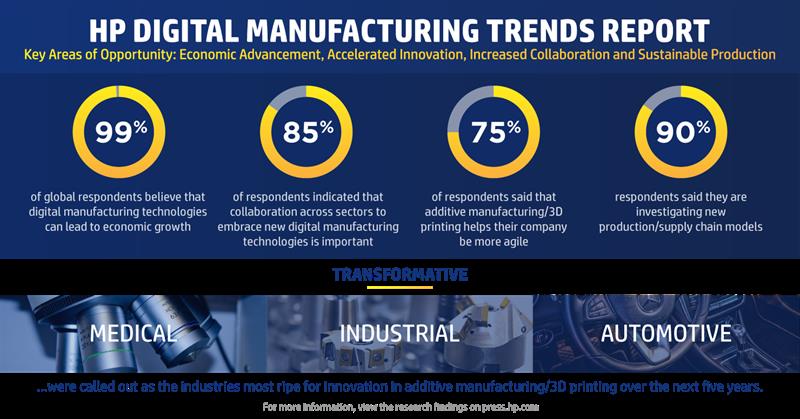

On top of this, manufacturing decision makers also see opportunities for accelerated innovation with additive manufacturing/3D printing, which is fuelling new areas of innovation in which UK companies are investigating. For example, 91% of respondents are looking to explore how mass customisation could be applicable to their business if parts could be personalised through additive manufacturing/3D printing. The medical, industrial and automotive industries were also called out as those most ripe for innovation in additive manufacturing/3D printing over the next 5 years.

“The global manufacturing sector is clearly signalling a desire for greater supply chain resiliency, more manufacturing flexibility, increased speed of innovation, and stronger environmental sustainability,” said George Brasher, MD UK & Ireland at HP. “And they are seeing industrial 3D printing as a way to not only lower costs and go to market faster, but as a unique competitive advantage that accelerates innovation for customers.”

Furthermore, digital manufacturing technologies are driving new opportunities for collaboration in the UK, with 82% indicating that their company have plans to collaborate with government entities on digital manufacturing products.

Sustainable production continues to be high on the agenda for the majority of manufacturing decision makers. Almost 9 in 10 (89%) agree that the recyclability of 3D printed powders and parts is a business imperative, whilst respondents were also keen (88%) to see governments incentivise the investment in and development of socially and environmentally beneficial digital manufacturing technologies.

HP’s Digital Manufacturing Trends Report Highlights Include:

Digital Manufacturing Technologies are Spurring Economic Advancement and Agility

- 99% of respondents believe that digital manufacturing technologies can lead to economic growth.

- 90% of respondents are looking to evolve their business models because of the current world business environment.

- 77% of respondents indicated that they will invest in digital manufacturing technologies in the next 12 months, with 86% indicating an expected investment increase in additive manufacturing/3D printing.

- 79% respondents said that additive manufacturing/3D printing helps their company be more agile, 79% is a viable alternative to traditional manufacturing, and 75% is a backup to traditional manufacturing.

- 92% of respondents said they are investigating new production/supply chain models, with 51% localised production and hybrid models, and 42% distributed supply chain.

Accelerated Innovation Transforms Industries

- The most cited benefit by respondents using additive manufacturing/3D printing is increased speed to market.

- The top new areas of innovation that companies are investigating are Mass customisation for direct to consumer products, production on demand, and Digital warehousing/virtual inventory.

- In particular, 93% of respondents want to explore the innovation that mass customisation provides and believe it could be applicable to their business if every part could be personalised through 3D printing/additive manufacturing.

- Medical, industrial, and dental/automotive tied were called out as the industries most ripe for innovation in additive manufacturing/3D printing over the next five years.

Opening Up New Opportunities for Collaboration

- 81% of respondents indicated that collaboration across sectors to embrace new digital manufacturing technologies is important.

- 82% indicated their company has future plans to collaborate with government entities on digital manufacturing products.

- To address the skills gap, 63% want to offer training services to professionals to prepare for additive manufacturing/3D printing, and 52% want to connect companies, governments, institutions, and citizens to work together to make investments in educational and job-skilling programs.

Sustainable Production Will Continue to Be a Business Imperative

- The top ways that additive manufacturing/3D printing can reduce waste and promote a circular economy are reducing the amount of materials used, and better matching of supply and demand.

- 89% of respondents said that the recyclability of additive manufacturing/3D printed powders and parts is important.

- 88% of respondents believes that it is important that governments create a sustainable ecosystem by incentivising investment in and development of socially and environmentally beneficial digital manufacturing technologies.