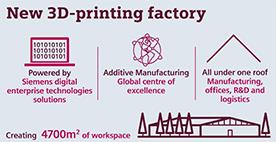

The site, which will open in September this year, will see the company increase its fleet of 3D printing machines from 15 to 50 in the next five years. The factory will be powered by Siemens Digital Enterprise technology.

The Materials Solutions workforce is also set to grow from its current 25 to 80 world-class engineers, metallurgists and manufacturing specialists – making the site a global centre of excellence for additive manufacturing. The facility will also act as a hub for collaboration between Materials Solutions and Siemens’ UK Digital Factory division

Materials Solutions, of which Siemens bought an 85% stake in 2016, specialises in additive manufacturing for the aviation, automotive, power generation and motorsport industries.

“This significant investment underlines our belief that there is huge potential for innovation and growth within the Additive Manufacturing sector. It is also the next step towards achieving our ambition of pioneering the industrialisation of 3D printing and demonstrates how we are leading the way for the fourth industrial revolution,” said Juergen Maier, Siemens UK CEO. “If the UK’s manufacturing sector is to grow and thrive, we must embrace digital technologies and build new industries based on them. Our vision and ambition for Materials Solutions perfectly represents how we are putting this strategy into practice.”

Phil Hatherley General Manager of Materials Solutions, said: “Our Worcester-based team are specialists in using Additive Manufacturing technology to solve complex engineering challenges for our customers across a range of sectors including aerospace, automotive and power generation. Our new facility will give us the space and scope to continue to innovate for these specialist and demanding industries and achieve a shift in the perception of 3D printing from being a technology associated with prototyping to a viable option for the serial production of additively manufactured parts.”

Hatherley continued: “We were incredibly proud to have achieved a world first last year – the production of a successfully tested 3D printed gas turbine blade – and I believe our new factory will facilitate similar achievements for our customers operating in other highly demanding environments, allowing us to maintain our position at the leading edge of this incredibly exciting industry.”